Choosing the Right Sump Pump for Philadelphia Homes: Expert Installation and Selection Guide

Choosing the Right Sump Pump for Philadelphia Homes: Expert Installation and Selection Guide

A sump pump is a mechanical device installed in a basement pit that automatically removes collected groundwater to protect a home from flooding and moisture damage. In Philadelphia, seasonal heavy rains, rapid snowmelt, and localized storm runoff make reliable sump pump installation and sizing a high-impact mitigation measure for basement waterproofing. This guide explains why sump pumps matter in Philadelphia, compares the main pump types, walks through how to size and select features, outlines the local installation process and permitting considerations, and gives concrete maintenance steps and cost/ROI context for homeowners. You will learn practical calculation examples for horsepower and GPM, pit and float-switch requirements, material trade-offs, and a clear installation checklist that helps you decide between DIY and professional services. Throughout the article we use Philadelphia-specific considerations—discharge planning, backup power choices, and integration with French drains and foundation repair—to help you choose a sump pump that protects health, preserves property value, and minimizes long-term repair risk.

Why Do Philadelphia Homes Need a Sump Pump?

A sump pump protects Philadelphia basements by collecting groundwater and actively pumping it away from the foundation, preventing standing water that leads to structural damage and mold growth. Philadelphia’s climate patterns—intense summer storms, spring snowmelt, and periodic high groundwater levels—create recurring infiltration risks that make passive drainage insufficient in many neighborhoods. Installing a sump pump reduces hydrostatic pressure against foundation walls and diverts water to permitted discharge points, which lowers mold risk and preserves finished basement living spaces and stored belongings. The next two subsections break down the local flood drivers and the functional mechanism that makes sump pumps effective in combating moisture and mold.

What Are the Flood Risks and Climate Challenges in Philadelphia?

Philadelphia experiences a mix of heavy rain events, localized urban runoff, and seasonal snowmelt that together increase the frequency and volume of water reaching residential foundations. Impervious surfaces and older stormwater systems in many neighborhoods can concentrate runoff, producing rapid basement infiltration during summer storms and spring thaws. Groundwater tables in low-lying areas can also rise seasonally, increasing the pressure on foundation walls and making interior drainage systems necessary. Understanding these local drivers clarifies why targeted solutions—sump pit sizing, discharge planning, and backup power—are essential components of a resilient sump pump installation in Philadelphia.

How Do Sump Pumps Prevent Basement Flooding and Mold Growth?

A sump pump prevents flooding by collecting water in a sump pit, activating via a float or electronic switch, and forcing water through a discharge line away from the foundation and into an approved outlet. This active removal reduces prolonged dampness and the cyclic wet-dry conditions that foster mold growth, while also protecting finishes, stored items, and mechanical equipment in basements. By lowering the local hydrostatic pressure, a properly sized sump pump can also reduce seepage through cracks and joints, decreasing the frequency of costly foundation repairs. The functional clarity of this mechanism leads directly into choosing the right pump type and backup strategy for Philadelphia’s intermittent power outages and heavy-storm scenarios.

What Are the Different Types of Sump Pumps for Philadelphia Homes?

Sump pumps fall into a few main categories—submersible, pedestal, battery-backup, and water-powered—each with specific performance, durability, and installation trade-offs that matter in Philadelphia’s conditions. Submersible pumps sit inside the pit and are typically more powerful and quieter, while pedestal units position the motor above the pit for easier maintenance and sometimes longer motor life. Backup options—battery or water-powered—address power-loss failure modes that are common during severe storms; selecting a backup depends on outage frequency, cost tolerance, and municipal water availability. The table and follow-up comparison provide an attribute-level view to help you match pump type to basement size, water-table exposure, and maintenance preferences.

This comparison shows that submersible pumps generally handle higher inflow and noisy conditions quietly, pedestal pumps are easier to service, and backup options directly address outage vulnerability. Next we compare submersible and pedestal pros and cons to help match selection to your property.

What Are the Pros and Cons of Submersible vs. Pedestal Sump Pumps?

Submersible pumps offer higher pumping capacity and quieter operation because the motor sits in the sump pit below floor level, but their submerged motors can be more exposed to wear from sediments and require pit access for replacement. Pedestal pumps keep the motor above the pit, which can simplify motor maintenance and reduce motor corrosion, though they typically provide lower flow rates and are noisier because the motor is above grade. Lifespan comparisons depend on duty cycle, water chemistry, and maintenance practices—heavy sediment or high usage shortens expected service life for any pump. Considering Philadelphia conditions—storm-driven surges and variable sediment—submersible models paired with good pit filtration are often recommended for high-risk basements, while pedestal units remain a cost-effective option for light-duty scenarios.

When Should You Consider Battery Backup or Water-Powered Sump Pumps?

Battery-backup systems are essential when your neighborhood experiences frequent storm-related power outages, as they provide limited run-time to handle the highest-risk hours during a storm. Water-powered backups rely on municipal water pressure and are attractive where long battery downtime is a concern, but they consume potable water and require sufficient pressure; they are not suitable in areas subject to boil-water advisories or where water conservation rules restrict discharge. Evaluate outage history, the value of finished basement space, and the criticality of protecting mechanicals and possessions to decide whether to invest in backup capability. The next section explains how to size a primary pump and choose features that balance capacity, cost, and durability.

How Do You Choose the Right Sump Pump Size and Features for Your Philadelphia Home?

Choosing the right sump pump requires translating expected inflow (GPM) and head height into horsepower, selecting a float switch type that matches pit geometry and debris risk, and picking materials that resist corrosion in wet conditions. Key considerations include basement square footage, soil saturation tendency, observed seepage rates during storms, vertical lift (head), and whether you plan to integrate the pump with a French drain or foundation drainage system. A worked calculation helps convert measured inflow or estimated rainfall/runoff into a GPM requirement, which then maps to a recommended horsepower range. After sizing, selecting materials—cast iron, stainless, or engineered thermoplastics—for motor housings and impellers will affect longevity and maintenance demands.

This table demonstrates how HP scales to GPM and helps match a pump to the expected inflow. The following subsection walks through a concrete example calculation to convert a measured inflow into recommended HP.

How to Calculate Horsepower and Pumping Capacity for Philadelphia Basements?

To estimate required capacity, start with an observed or estimated inflow rate in gallons per hour (GPH) during a storm and convert to gallons per minute (GPM) by dividing by 60. Account for head height—the vertical distance the pump must lift water—and reduce available GPM per manufacturer pump curves at the expected head; then select the nearest higher HP rating to provide a safety margin. Example: if a small basement shows 1,800 GPH during a heavy rain event, that equals 30 GPM; factoring a 10–15 ft head suggests a 1/3 HP pump or higher to maintain reliable flow with margin. Because pump curves and actual site head vary, a professional on-site assessment remains the most reliable way to finalize HP and impeller selection.

Sump Pump Effectiveness in Reducing Residential Infiltration and Inflow

Monitoring Effectiveness of Sump Pump on Reducing Private Infiltration/InflowAbstractCity of Columbus, Ohio has chosen a source control approach to solve wet weather sanitary sewer overflow problems and achieve Ohio EPA consent decree requirements. The source control approach includes lining private sanitary laterals, redirecting roof downspouts to streets, and installing voluntary sump pumps in residential homes. Past studies and monitoring have demonstrated the effectiveness of lateral lining on reducing private source infiltration/inflow (I/I), however not sufficient monitoring has been performed on effectiveness of sump pump. Prior to implementing the sump pump program in full scale, City of Columbus conducted a pilot project of 118 sump pump installation with 25 sump pumps being monitored for over 18-months since November 2016. The monitoring program is to quantify peak I/I reduction and explore ways to improve sump pump effectiveness. The monitoring program includes time-stamped

Monitoring Effectiveness of Sump Pump on Reducing Private Infiltration/Inflow, 2018

Pilot studies have shown that sump pumps can be an effective tool in reducing the amount of water entering residential sewer systems, highlighting their role in managing inflow and infiltration.

What Are the Important Sump Pit and Float Switch Requirements?

Sump pit dimensions and float-switch choice strongly affect reliability: a common practical minimum pit diameter for residential installations is typically wide enough to permit float movement and service access, while deeper pits add storage volume between pump cycles. Float switches come in tethered, vertical, and sealed electronic types; tethered floats can snag on debris, vertical floats provide consistent activation in tight spaces, and electronic sensors offer compact profiles with fewer moving parts. Position the float to avoid interference with inlet drains and check valves, and ensure the pit has a cleanable grate or filter to reduce sediment ingress. Thoughtful pit and switch configuration reduces short-cycling and premature motor wear, making the pump selection more durable over time.

How Do Material Choices Affect Sump Pump Durability and Cost?

Material choices for housings, impellers, and discharge piping impact longevity and maintenance frequency: cast iron motors offer robustness and weight that dampens vibration but can corrode if untreated; stainless components resist corrosion but add cost; engineered plastics provide chemical resistance and lower expense with modern performance. Lifespan expectations hinge on workload—higher duty cycles shorten life regardless of materials—so selecting a material that balances corrosion resistance with budget and expected usage is key. Warranties and manufacturer support are also important indicators of anticipated durability; pair material selection with a routine maintenance plan to maximize life and performance.

What Is the Sump Pump Installation Process in Philadelphia?

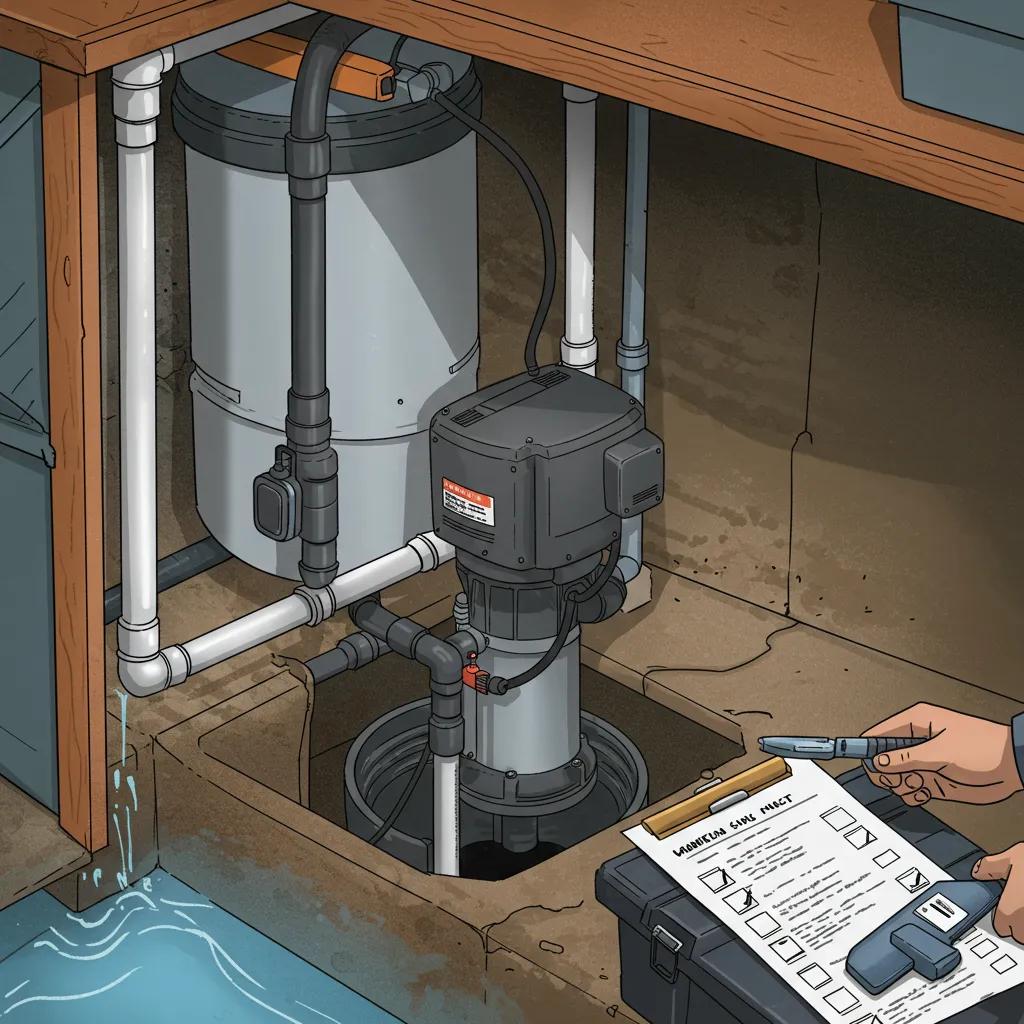

A standard sump pump installation sequence in Philadelphia begins with a site assessment to confirm infiltration sources, pit location, and discharge routing, followed by pit excavation or modification, pump placement, plumbing and check-valve installation, electrical hook-up to a GFCI-protected circuit, and a comprehensive test under simulated high-water conditions. Philadelphia homeowners must confirm local discharge requirements and potential permit needs before finalizing installation, and the process should include thoughtful discharge routing to prevent neighbor impacts and municipal violations. Choosing a professional installer often reduces permitting and electrical risks and ensures integration with other basement waterproofing systems like French drains and foundation crack repair. The numbered installation checklist below provides a concise, stepwise featured-snippet–friendly view of the typical workflow.

- Perform an on-site assessment to determine pit location, flow rates, and discharge routing.

- Excavate or modify the sump pit and prepare a stable, level base for the pump.

- Install the pump, check valve, and discharge piping, routing discharge to an approved outlet.

- Complete electrical wiring to a dedicated GFCI circuit, perform functional testing, and document the installation.

This ordered list outlines the major phases of installation and clarifies how each stage reduces flood risk; the next subsection summarizes permit considerations and the DIY vs. professional decision context.

What Permits and Regulations Must Philadelphia Homeowners Follow?

Philadelphia homeowners should confirm municipal requirements for sump pump discharge location and any building permits related to electrical or structural work, as rules often specify minimum distances and approved outlets to avoid discharging into public storm drains in restricted ways. Typical permit pathways require submitting basic work descriptions for electrical circuits or significant excavation; checking with local inspection departments prevents costly rework or fines. For complex drainage routing or when integrating a pump with a French drain or foundation repair, professional installers can advise on permitted discharge options and coordinate inspections. Understanding these local regulatory touchpoints before work begins reduces delays and aligns the installation with city standards.

Should You Hire a Professional or Attempt DIY Installation?

Hiring a licensed professional reduces risks from improper electrical connections, inadequate discharge routing, and voided warranties, while DIY installation can be practical for experienced homeowners replacing an identical pump in an existing compliant pit. Professional installation is recommended when permits, complex pit modifications, integration with other waterproofing systems, or battery-backup integration are required—these scenarios involve trade-offs in safety, insurance, and long-term performance. If you choose DIY, follow manufacturer instructions precisely, ensure electrical work meets code, and confirm discharge routing conforms with municipal rules. For many Philadelphia homeowners, the peace of mind from a licensed, insured installer outweighs the marginal labor savings of DIY.

Short note on professional workflow (MBB Basement Waterproofing): MBB Basement Waterproofing brings local experience and a structured installation workflow to Philadelphia sump pump projects, including on-site assessment, permit guidance, coordinated pit and plumbing work, and final testing. As a licensed and insured local provider with comprehensive basement waterproofing services, MBB can recommend the optimal pump type and backup strategy during an on-site evaluation and coordinate any necessary permits and inspections.

How Should Philadelphia Homeowners Maintain Their Sump Pumps for Longevity?

Regular maintenance extends pump life, prevents failure during storms, and preserves warranty coverage; a seasonal and annual checklist helps homeowners monitor pit cleanliness, test float activation, verify discharge flow, and exercise battery backups. Monthly visual checks and periodic in-situ tests simulate high-water conditions to confirm automatic activation and identify noisy bearings or excessive cycling that signal wear. Annual professional inspections complement homeowner checks by testing performance under load, checking electrical integrity, and inspecting check valves and discharge routing for blockages. The checklist below provides clear, actionable tasks organized by frequency to keep a sump pump reliable through Philadelphia’s storm seasons.

Maintenance checklist introduction paragraph: follow these inspections and tests to maximize reliability and catch early failure signs. Monthly and seasonal items keep the system operational, while annual professional checks address hidden wear and electrical safety. Consistent maintenance reduces the risk of failure during high-stress storm periods and extends component life. Implementing this schedule makes backup systems more effective when they are needed most.

- Monthly: Inspect the sump pit and remove debris, verify float movement, and confirm the pump is upright and connected.

- Seasonal: Simulate a full activation by pouring water into the pit, verify discharge threading and check-valve operation, and inspect discharge termination for freezing risks in winter.

- Annual: Replace battery backup cells if present, schedule professional electrical and pump load test, and inspect pit liner and piping for wear.

What Is the Recommended Maintenance Schedule and Checklist?

A practical maintenance rhythm combines monthly visual checks, seasonal activation tests before storm seasons, and an annual professional inspection for electrical and mechanical integrity. Monthly checks focus on pit cleanliness and unobstructed float operation; seasonal tests involve filling the pit to validate automatic start/stop behavior and observing discharge flow to the final outlet. Annual inspection tasks include load testing the pump under simulated high inflow, verifying the GFCI-protected circuit, evaluating check valves for seal integrity, and testing any battery-backup runtime. Establishing this predictable cadence reduces the likelihood of surprise failure and integrates well with broader basement waterproofing maintenance.

How Can You Identify Common Sump Pump Problems and When to Replace?

Common failure signs include unusual noise levels, frequent short cycling (indicating improper float or oversized pit), failure to run during simulated tests, and visible corrosion or leaks around seals and piping. If a pump fails during a storm or shows progressive performance decline—reduced discharge flow or overheating—replacement is prudent, as continued operation risks motor burnout and basement flooding. Replacement triggers commonly include repeated failures, age beyond the manufacturer’s expected lifespan, or inability to meet required GPM at site head conditions. When symptoms appear, pair immediate troubleshooting (cleaning intake screens, testing switches) with a professional assessment to determine whether repair or replacement yields better long-term reliability.

What Are the Typical Costs and ROI of Sump Pump Installation in Philadelphia?

Sump pump installation costs vary by pump type, pit work, discharge complexity, electrical work, and permitting; evaluating ROI involves comparing installation investment against avoided water damage, mold remediation, and potential loss of finished space. Major cost contributors include the pump unit itself, labor for pit excavation and plumbing, electrical circuit installation, discharge piping and terminations, and any required permits or inspections. Investing in backup systems and higher-quality materials raises upfront cost but often reduces replacement frequency and emergency repair expenses. The table below breaks down common cost contributors so homeowners can compare low/average/high scenarios and calculate simple ROI based on avoided repair bills and protection of finished basement value.

What Factors Influence Sump Pump Installation Costs in Philadelphia?

Key cost drivers include pump type and horsepower, pit excavation complexity, required discharge routing distance, electrical work to install a dedicated GFCI circuit, and any permit or inspection fees tied to local regulations. Additional waterproofing needs—such as tying into an interior French drain, addressing foundation cracks, or installing a battery-backup system—raise scope and cost but improve system resilience. Access challenges, below-grade obstructions, and requirement for masonry or concrete repair after pit work further increase labor time and materials. Because these variables change per property, an on-site assessment that quantifies inflow, head, pit condition, and discharge options is the most reliable way to produce an accurate cost estimate.

Short MBB Basement Waterproofing value paragraph and CTA: For Philadelphia homeowners seeking a professional path to reliable basement protection, MBB Basement Waterproofing offers licensed and insured sump pump installation as part of its comprehensive basement waterproofing services. With over 20 years of local experience, free estimates, and flexible payment plans, MBB combines permit guidance, installation expertise, and integration with French drain and foundation repair services. Homeowners planning a project can request a free estimate and on-site assessment to receive a tailored scope and cost breakdown that aligns with local code and site conditions.

Lists and summary paragraph for costs and ROI: When assessing ROI, consider avoided repair costs, preservation of finished basement value, insurance implications, and long-term maintenance outlays. The right investment not only reduces immediate flood risk but also limits mold remediation expenses and potential structural repairs. A professional estimate helps quantify these benefits and informs a clear decision about pump type and backup options.

- Avoided Repair Costs: A working sump pump reduces the likelihood of structural and content damage during storms.

- Mold Remediation Savings: Preventing sustained dampness lowers the chance of costly mold removal and health-related issues.

- Property Value Protection: A dry, protected basement maintains usable square footage and resale value.

Why Choose MBB Basement Waterproofing for Your Sump Pump Needs?

MBB Basement Waterproofing provides localized expertise and service continuity for Philadelphia sump pump projects, combining permit assistance, installation skill, and integration with broader waterproofing services such as French drains and foundation repair. The company is PA licensed and insured, offers free estimates to help homeowners evaluate options at no initial cost, and provides flexible payment plans to make comprehensive basement protection more accessible. With a focus on quality and customer satisfaction and over 20 years of local experience, MBB positions itself as a partner for homeowners seeking a reliable, code-compliant installation. To move forward, homeowners are encouraged to request a free estimate and on-site assessment to determine the right solution for their property.

Frequently Asked Questions

What is the average lifespan of a sump pump?

The average lifespan of a sump pump typically ranges from 5 to 10 years, depending on usage, maintenance, and the type of pump. Submersible pumps, which are often more powerful, may last around 5 to 7 years, while pedestal pumps can last longer due to their motor being above the water level, reducing wear from moisture. Regular maintenance, such as cleaning the sump pit and testing the pump, can help extend its lifespan and ensure reliable operation during critical times.

How often should I test my sump pump?

It is recommended to test your sump pump at least once a month, especially before the rainy season. To test, pour water into the sump pit to see if the pump activates and removes the water efficiently. Additionally, performing a more thorough test seasonally by simulating heavy rain conditions can help ensure that the pump is functioning correctly. Regular testing helps identify potential issues early, preventing failures during critical times.

Can I install a sump pump myself?

While some homeowners may choose to install a sump pump themselves, it is often recommended to hire a professional, especially if electrical work or complex plumbing is involved. DIY installation can be feasible for experienced individuals replacing an existing pump in a compliant pit. However, professional installers ensure proper integration with existing systems, compliance with local regulations, and reduce risks associated with improper installation, which can lead to costly repairs or failures.

What maintenance is required for a sump pump?

Regular maintenance for a sump pump includes monthly visual inspections, seasonal activation tests, and annual professional check-ups. Monthly tasks involve cleaning the sump pit, verifying float movement, and ensuring the pump is connected properly. Seasonal tests should simulate high-water conditions to confirm the pump activates correctly. An annual inspection by a professional can assess electrical integrity and check for wear, ensuring the pump remains reliable and effective throughout its lifespan.

What should I do if my sump pump fails?

If your sump pump fails, first check for common issues such as power supply problems, clogged discharge lines, or malfunctioning float switches. If the pump does not activate during a test or shows signs of wear, it may need repair or replacement. In case of severe flooding, consider using a backup pump or contacting a professional immediately to prevent water damage. Regular maintenance can help identify potential failures before they occur, reducing the risk of emergency situations.

Are battery backup sump pumps worth the investment?

Battery backup sump pumps are often worth the investment, especially in areas prone to power outages during storms. They provide essential protection by ensuring that the sump pump continues to operate even when the main power supply is interrupted. This can be crucial for preventing flooding and water damage in basements. While they add to the initial cost, the peace of mind and protection they offer can save homeowners from costly repairs and damage in the long run.

How do I choose the right sump pump for my home?

Choosing the right sump pump involves assessing your home’s specific needs, including the size of your basement, expected water inflow, and local climate conditions. Consider factors such as horsepower, pump type (submersible or pedestal), and whether you need a backup system. It’s also important to evaluate the materials used in the pump for durability. Consulting with a professional can provide tailored recommendations based on your unique situation, ensuring you select a pump that effectively protects your home from flooding.

Conclusion

Choosing the right sump pump is essential for protecting Philadelphia homes from flooding and moisture damage, ensuring a safe and dry living environment. By understanding the local climate challenges and selecting the appropriate pump type, homeowners can significantly reduce the risk of costly repairs and preserve their property value. Regular maintenance and professional installation further enhance the longevity and effectiveness of these systems. For expert guidance and a tailored solution, request a free estimate from MBB Basement Waterproofing today.